- Home

- About A-FOOTPRINT

- Expected Results

Beyond State of the Art

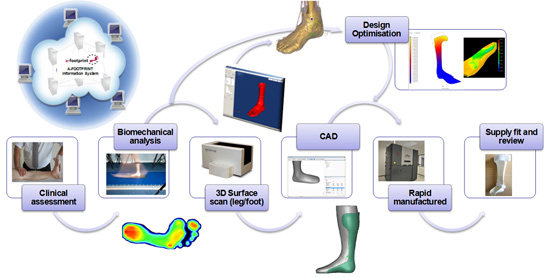

A-FOOTPRINT aims to develop, verify and deliver a new custom-made orthotic value chain. This value chain exploits new capabilities in additive manufacture and digital enabling technologies.

A new value chain

John’s new journey starts with a clinical assessment and prescription which is entered to the A-FOOTPRINT information system database (AFIS).

3D digital scanning

John has his leg scanned using a 3D digital scanner. The scan is transferred and stored on the AFIS system.

Optimised to be 30% lighter

John’s AFO is computer-aided designed in the new POD CAD system. Since John finds his original AFO heavy and cumbersome his design is personally optimised so that it is 30% lighter but retains its stiffness. This will maximise his walking function by stabilising his foot and ankle.

Personalisation

The design is transferred to the Rapid Manufacturing Machine and built using selective laser sintering (SLS). This is an automated process. The finished device has some additional personalised features for John including his chosen colour and surface finish and engraved name, order number and date of issue.

The 48 hour process

John’s device is built overnight and he is fitted with the device within 48 hours. The clinical information, 3-D surface scan, AFO CAD design and SLS build specifications are stored in the AFIS system. Should John require a replacement device this can be built and supplied to John within 48 hours.

Find out how long this process takes without the A-FOOTPRINT concept.